What is Structural Steel Fabrication?

Structural steel fabrication is the process of shaping raw steel into specific forms and dimensions to build the frameworks of structures like buildings, bridges, and other infrastructure. This approach is essential to produce robust and durable buildings that meet modern engineering standards.

Steel structure manufacturers play a key role in the modern construction and infrastructure sectors, with their business scope spanning from the production of basic components to full-process engineering delivery. Manufacturers of all sizes offer differentiated solutions to meet the diverse engineering needs of the market, based on their respective strengths.

Structural Steel Fabrication Process

Steel fabrication involves multiple stages, each requiring precise craftsmanship and specialized skills. The main steps include:

·Design and Planning

Before fabrication begins, engineers and architects create detailed blueprints using computer-aided design (CAD) software. These designs specify dimensions, materials, load-bearing requirements and welding details. Proper planning ensures that fabricated parts will fit perfectly during assembly.

·Cutting and forming

Raw steel sections, such as beams, channels and plates, are cut into the desired shape using a variety of techniques:

·Shearing: Straight cuts are made using large blades.

·Sawing: for thicker sections.

Plasma and laser cutting: Highly accurate cutting methods used for complex shapes.

Flame cutting: Uses a flame to cut thick steel plates.

After cutting, the steel piece may be bent, rolled or stamped to achieve the desired shape.

·Welding and Assembly

Welding is a critical step in the joining of steel parts and the following techniques are used in the welding process:

Electric arc welding (SMAW, GMAW, FCAW)

·TIG and MIG welding

Spot welding of thin plates

Skilled welders ensure that the joints are strong and free of defects, in accordance with industry standards.

·Surface treatment and finishing

To improve durability and prevent corrosion, steel is treated as follows:

Sandblasting or shot blasting to remove rust and impurities.

Primed and painted to protect against environmental factors.

Galvanized (zinc coated) to ensure long term protection against rust.

·Quality Control and Inspection

Manufactured components are inspected for dimensional accuracy, weld integrity and structural soundness. Non-destructive testing (NDT) methods such as Ultrasonic Testing (UT) and Magnetic Particle Inspection (MPI) detect hidden defects.

·Transportation and erection

Once approved, the prefabricated steel will be transported to the construction site and assembled using bolts, rivets, or additional welding.

Common processing technologies in Structural Steel manufacturing

Application of Structural Steel fabrication

Steel fabrication is widely used in various industries due to its high strength and adaptability:

Building Construction

·Commercial buildings: skyscrapers, office buildings and shopping centers.

– Residential buildings: steel-framed houses and apartment buildings.

– Industrial facilities: factories, warehouses and power plants.

·Infrastructure Projects

– Bridges and overpasses: steel has high load-bearing capacity.

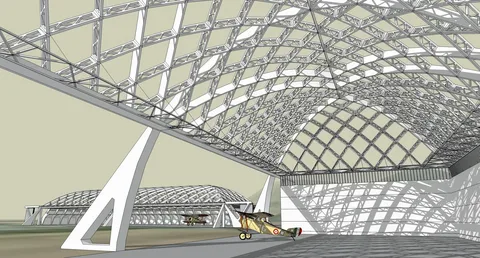

– Stadiums: large-span structures require the flexibility of steel.

– Airports and train stations: steel supports wide roofs and frames.

·Specialty Structures

– Transmission towers: steel’s durability allows it to withstand harsh weather.

– Offshore platforms: resistance to corrosion in the marine environment.

– Mining and oil rigs: heavy steel structures for extreme conditions.

Advantages of Structural Steel Fabrication

·Strength and Durability

Steel has a high strength-to-weight ratio, making it ideal for large structures that must withstand heavy loads, earthquakes and extreme weather.

·Design Flexibility

Steel can be molded into complex shapes, allowing architects to create innovative designs that would be difficult to achieve with other materials.

·Cost Effectiveness

While the initial cost of steel may be higher than wood or concrete, its long life and low maintenance costs reduce long-term costs.

·Sustainability

Steel is 100% recyclable, reducing its impact on the environment. Prefabrication also minimizes construction waste.

·Speed of construction

Since the components are prefabricated off-site, assembly is faster compared to traditional construction methods.

Challenges in Structural Steel Fabrication

·Shortage of skilled workers

Structural Steel fabrication requires highly skilled workers proficient in precision welding, cutting and assembly. However, the industry faces a growing shortage of qualified labor due to an aging workforce and inadequate training programs. This shortage can lead to project delays, increased labor costs, and potential quality control issues.

·Corrosion risk

Steel is susceptible to oxidation, especially in harsh environments such as coastal areas or high humidity areas. Without proper protective coatings (e.g., galvanized, epoxy, or paint systems), corrosion can compromise structural integrity over time, leading to costly maintenance or premature failure.

·High initial cost

The fabrication process requires advanced mechanical equipment (e.g., CNC cutting systems, robotic welders) and high-quality raw materials, which can lead to significant upfront costs. In addition, specialized engineering and design expertise further increases the initial cost of the project compared to other construction methods.

·Transportation and handling challenges

Large, heavy steel components often require specialized logistics for transportation, including oversize load permits, reinforced transport vehicles, and on-site crane operations. Improper handling during transportation can result in deformation or damage to the components, requiring rework and delays to the construction schedule.

Conclusion

Structural steel fabrication plays a key role in contemporary construction, with key benefits including superior strength, design adaptability, rapid assembly and environmental sustainability. By mastering the intricacies of steel fabrication, construction professionals, from engineers to contractors, can ensure projects are executed efficiently and economically with quality and safety. As the construction industry continues to evolve, steel fabrication will remain indispensable in building the durable and innovative infrastructure needed to meet the challenges of the future.