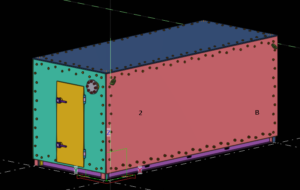

Israel Camping Box MIC Project – Steel Structure Processing Showcase

As a professional steel structure processing company, we specialize in handling every stage of fabrication — from incoming material inspection, precision cutting, welding, and assembly to beveling, sandblasting, and protective painting. Our goal is to deliver reliable, safe, and durable steel structures that meet international construction standards.

One of our recent works is the Israel Camping Box MIC Project, which required high-quality fabrication and strict attention to detail.

Project Overview

- Location: Israel

- Type: Camping Box MIC steel structure

- Scope: Full-cycle steel processing and fabrication

Engineering Challenges & Solutions

- Tight Tolerance Requirements

- Camping boxes require precise cutting and welding to ensure proper assembly and long-term durability.

- We applied advanced CNC cutting and welding techniques to achieve high accuracy.

- Corrosion Resistance in Outdoor Use

- Since the project involves outdoor camping facilities, surface protection was critical.

- We used sandblasting + industrial-grade painting to enhance corrosion resistance and extend service life.

- Efficient Assembly & Modular Design

- The camping boxes needed to be easy to assemble on-site.

- Our team optimized the beveling and prefabricated assembly process, reducing installation time for the client.

Why It Matters for Contractors & Designers

- Quality Assurance: From raw material to final painting, each step was carefully inspected.

- Engineering Support: We solved fabrication challenges that ensured smooth construction on-site.

- Value to Client: Delivered a robust, modular, and durable steel structure, perfectly suited for outdoor applications.