As a professional steel structure manufacturer, we are honored to have participated in the fabrication and installation of steel structures for several key projects at Hong Kong International Airport. This article details our high-standard steel structure technologies applied in airport projects, including AESS-standard facade structures, temporary steel truss systems, and prefabricated light steel structures.

AESS Standard Steel Facade Fabrication for Hong Kong Airport

The Architecturally Exposed Structural Steel (AESS) standard is a core requirement for Hong Kong Airport’s facade engineering. We strictly adhere to this international standard to deliver high-quality steel structure solutions.

- Precision Fabrication: Utilizing CNC cutting and automated welding technology to ensure dimensional accuracy within ±1mm

- Surface Treatment: Compliant with AESS Category C standards, including sandblasting and three-layer anti-corrosion coating system

- Quality Control: Full traceability system from raw materials to finished products

Our AESS-standard steel structures have been successfully applied in the T1 terminal expansion project, delivering over 8,500 tons of high-quality facade support structures.

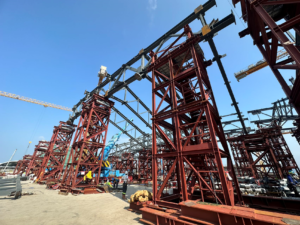

Engineering Practice of Temporary Steel Truss Systems for Airports

During Hong Kong Airport’s renovation and expansion, we provided temporary steel truss solutions to ensure uninterrupted airport operations:

- Rapid Deployment Design: Modular design enables installation speeds averaging 200㎡/day

- Load Optimization: Finite element analysis improves designs, reducing weight by 15% while increasing load capacity by 20%

- Safety Standards: Compliant with Hong Kong’s Buildings Ordinance and British Standard BS 5950

For the recent satellite concourse project, we delivered a 72-meter span temporary steel truss system supporting over 18,000㎡ of temporary operational space.

Advantages of Prefabricated Light Steel Structures in Airport Projects

For Hong Kong Airport’s Prefabricated Light Steel Structure requirements, we developed specialized solutions:

- Fast Construction: 85% factory prefabrication reduces on-site construction time by 40%

- Lightweight Design: Using high-strength steel (S460ML), structures are 30% lighter than conventional solutions

- Roof Systems: Innovative space truss designs enable column-free large spans (maximum 58m)

Our prefabricated light steel structures have been used in multiple airport ancillary facilities including cargo terminals and maintenance hangars, totaling over 120,000㎡.

Quality Assurance System for Steel Structure Fabrication

To ensure exceptional quality for Hong Kong Airport projects, we implement strict quality control:

- Material Certification: All steel complies with ASTM A572 Grade 50 standards with 3.1 material certificates

- Welding Standards: AWS D1.1 and EN 1090 EXC3 compliance with 100% ultrasonic testing for critical welds

- Corrosion Protection: Hot-dip galvanizing (average zinc coating ≥85μm) with special topcoat systems

We hold Hong Kong Development Bureau-recognized steel fabrication qualifications and ISO 9001:2015 certification.

Why Choose Us as Your Airport Steel Structure Supplier?

With 20 years of specialization in steel structures, we offer unique advantages:

✓ Extensive Experience: Completed 17 airport-related steel projects, including 5 international hub airports

✓ Technical Capabilities: BIM Level 2 design capability and complex node fabrication technology

✓ Delivery Assurance: 120,000㎡ production facility with monthly capacity of 4,500 tons

✓ International Standards: Familiar with and compliant with UK, Hong Kong, and international aviation facility standards

We look forward to providing more high-quality steel solutions for Hong Kong Airport’s upcoming projects, including the planned third runway supporting facilities.

For more information about our airport steel structure solutions, please contact our engineering team. We offer professional technical consultation and customized project services to help build world-class aviation hub facilities.