Steel Structures in Airport Applications

As a leading steel structure company, we understand the critical role of **high-performance steel buildings** in modern airport construction. Steel offers unmatched strength, durability, and design flexibility, making it the ideal choice for airport terminals, hangars, control towers, and more

Key Applications of Steel Structures in Airports

1. Airport Terminals & Concourses

– Large Clear Spans: Steel allows column-free spaces, optimizing passenger flow and retail layouts.

– Modular Expansion: Easy to extend terminals as passenger demand grows.

– Aesthetic Flexibility: Curved roofs, glass facades, and modern designs enhance visual appeal.

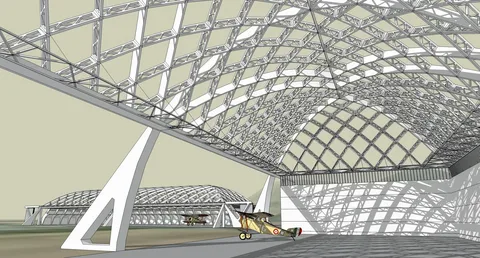

2. Aircraft Hangars & Maintenance Facilities

– Wide Spans (100m+): Steel trusses and space frames accommodate large aircraft (e.g., Boeing 747, Airbus A380).

– Quick Construction: Pre-engineered steel buildings (PEBs) reduce build time vs. traditional methods.

– Durability: Resistant to corrosion, heavy loads, and extreme weather.

3. Control Towers

– High-Strength Framework: Steel ensures stability for tall, slender structures with 360° visibility.

– Seismic & Wind Resistance: Critical for safety in earthquake-prone regions.

4. Cargo Warehouses & Logistics Centers

– High Bay Storage: Steel structures support mezzanine floors and automated storage systems.

– Fire Resistance: Fireproof coatings protect steel in high-risk zones.

5. Canopies & Drop-off Areas

– Lightweight & Elegant: Steel-and-glass canopies provide weather protection with minimal supports.

Why Choose Steel for Airport Projects? ✅

✔ Speed of Construction – Prefabricated components enable faster assembly.

✔ Cost Efficiency – Lower foundation costs, reduced labor, and minimal maintenance.

✔ Sustainability – Recyclable material, energy-efficient designs (solar-ready roofs).

✔ Safety & Compliance – Meets international aviation standards (ICAO, FAA).

—

Our Expertise in Airport Steel Structures

We specialize in:

– Custom-engineered steel solutions for airports of all sizes.

– PEB (Pre-Engineered Buildings) for rapid deployment.

– Seismic & wind-resistant designs for extreme conditions.

– Cladding & insulation systems for energy efficiency.

Contact us today to discuss your airport project! 🚀

Production Process

Our Equipments

Frequently Aked Questions

Tongzhou Steel Structures has served a variety of industrial, commercial, agricultural, and residential constructions. Our projects have applied to the chemical, food, automotive, store, packaging, manufacturing, and other industries.

1.What types of steel structures do you manufacture?

- 1, TTS can produce MIC steel structure.

- 2, Industrial Structures – Power plants, oil & gas facilities, conveyor systems.

- 3, Commercial Buildings – Offices, shopping malls, stadiums.

- 4, Custom Fabrications – Staircases, platforms, steel frames

2.How can I get the price from you?

To provide you with an accurate price, we’ll need a few key details about your project. This ensures the quote is tailored to your needs.

Ask for specifics such as:

Design drawings (if available: CAD, PDF, or sketches).

Dimensions (length, width, height, span).

Material preferences (e.g., Q235B, Q355B steel, galvanized, etc.).

Load requirements (snow/wind loads, seismic zone, crane systems).

Surface treatment (painting, galvanizing, fireproofing).

Delivery location & timeline.

Option 1: You can email us the details at nieguanjun@tongzhousteel.com, and we’ll respond with a quote within 3 days.

Option 2: We can arrange a quick call or meeting to review your needs—when works best for you?

3.What is your payment term?

We use bank transfers (TT) for international clients to ensure transparency. All terms are formalized in our contract.

30% deposit (to secure materials and start production)

70% upon fabrication completion (before delivery)

We’re happy to discuss adjustments based on your company’s policies.

4.What is your warranty?What can we do in case of problems?

EN1090, ISO3834 quality system

The whole process quality control, such as material inspection, fit up inspection, dimension inspection, blasting and coating inspection.

5.How do you ensure quality control?

3rd party NDT and material retest service

ISO9001, EN1090, ISO3834 quality system

The whole process quality control, such as material inspection, fit up inspection, dimension inspection, blasting and coating inspection.

6.Can you work with my architect/contractor?

7.What if I need modifications after production starts?

Client can send design change drawing to us, TTS technical engineer will issue the design change notice to workshop.

8.Can you match special color codes?

Jotun, international paint, PPG paint colors are available.

9.Can you fabricate curved or architecturally complex steel structures?

Yes, we have CNC bending machines and experience with complex geometries (e.g., arches, domes).

10.Do you provide anti-corrosion treatments?

TTS can provide blasting+painting service, TTS can help client to search hot dip galvanize service.